EZ Skid™ Standard Product Description – By Hydro-Thermal

EZ Skid

The EZ Skid is an integrated, compact pre-engineered heating system, utilizing the direct steam injection EZ Heater. All components needed for correct application are included; simply connect to plant utilities: steam, water, air and power.

» Available in 5 standard sizes with ratings to 1,350 GPM [306 m /hr]

» Highly compact to meet space constraints

» Pre-designed and partially stocked for short lead time

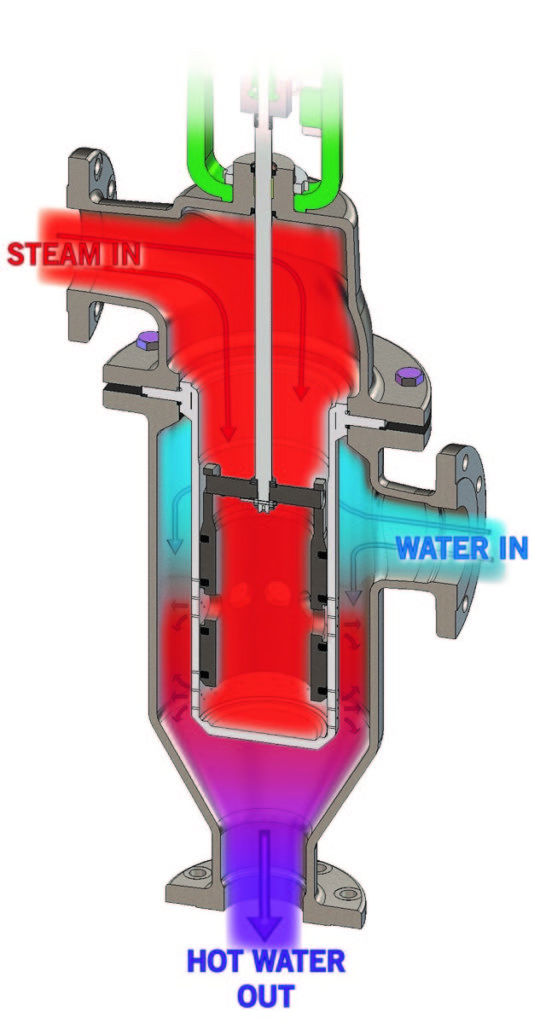

EZ Heater

» Patented design for effective heat transfer, utilizing internal modulation for precise temperature control and predictable results. See “EZ Heater Product Brochure” for further details.

» Designed using the choked flow principle for excellent steam/water mixing, stable and self-cleaning operation.

» Utilizes an internal seal that meets Class II leakage requirements.

» Units are equipped with electro-pneumatic positioners (Fisher DVC6200AC on 3”, 4”, and 6” units; DVC2000AC on smaller units).

Steam and Water Piping Components

» Provided with an automatic on/off steam valve, which isolates steam when the unit is disabled. This is a high-performance

» Provided with a steam strainer to prevent damage to system components. Includes manual blow off valves.

» Steam inlet piping complete with drip leg, thermostatic steam trap and blow-off valve to prevent condensate accumulation during start-up and shutdowns.

» Includes check valves on the steam and water supply to assure that under upset conditions, water will not enter the steam piping or steam will not enter the upstream water piping. Check valves are spring-assisted silent check valves.

Instrumentation

» Paddle wheel flow sensor is used to measure water flow, serving as a protective device for no-flow condition. This also enables flow logging through the Hydro-Thermal controller.

» Temperature elements: PT100 RTD or thermocouple direct immersion temperature sensors on water inlet and outlet.

» Provided with pressure gauges for the steam and water piping. Isolation valves provided, along with steam siphon on the steam lines

Ratings and Material of Construction

» The EZ Heater and all components are rated for 150 psig [10 barg]. The EZ Heater is rated at 195 psig [13.4 barg] at 400°F [205°C].

» EZ Heater bodies are cast 316 Stainless Steel, with 316L internals.

» Water piping is 304 Stainless steel, sch 40. Steam piping is carbon steel, sch.40.

» The frame is welded tubing, 304 Stainless steel.

» Steam system components are carbon steel, with stainless steel internals as required for performance.

» Some components utilize carbon steel bodies with stainless steel trim (larger check valves, automatic on/off steam valves, pumps, etc).

Controls

Hydro-Thermal proprietary controller is designed to respond to a wide range of flow conditions with a high degree of accuracy. The controller is designed as a dedicated control for the EZ Skid, with some plant interface possible. See “SMART Controller” for further details.

Accuracy of temperature control depends on flow turn-down and flow rate variation. Highly variable or rapidly changing flows require a re-circulation pump and fast response features. We can recommend the most cost-effective controls for your application.

Options

» The EZ Skid can be provided with an optional internal re-circulation pump, designed to handle high turn-down or rapidly varying flow rates. The pumps can also be provided for plant re-circulation, to maintain the water piping system at design temperature.

- Pumps are industrial-class, stainless steel casings with stainless steel internals rated for the system temperatures and pressures. Pump design flow and head dependent on application.

» Fast-response feature might require a re-circulation pump.

» Back-pressure valve for closed loop applications can be integrally-mounted.

» Special materials or components available upon request, but will extend lead time.

Utilities

» Steam and Water – see the proposal sizing sheet for details

» Instrument Air: 60 psig [4 barg], clean dry air needed

» Electric:

- Controller – 120VAC, 1-phase, 5A

- Recirculation Pump – 230/460VAC, 3-phase (horsepower dependent on application)

Call R-Cap today for a quote: 847.382.3003

Email R-Cap today for a quote: tanksandmixers@r-cap.com

Comments are closed.